Thermal-HS Infrared Hot Spot Detection Microscopy:

A traditional approach to finding shorts in semiconductor devices has been liquid crystal investigation. Unfortunately, liquid crystal investigations have several limitations: low sensitivity (especially from the backside), slow response, operator exposure to bio-hazardous materials, difficulties with application and interpretation. QFI’s Thermal-HS medium wave infrared (MWIR) hot spot sensor locates ohmic faults from their self-heating. Heat radiates in the infrared spectral range, and the QFI’s MWIR sensors are capable of capturing these radiant emissions. Custom objective lenses made with infrared transmissive materials such as silicon, germanium, sapphire, and zinc selenide complete the optical path between DUT and sensor. Silicon is transparent in the MWIR and heat-generating defects emit in an isotropic manner. Therefore, the hot spot sensors work well in front side and backside applications. The Thermal-HS solution incorporates unique application software and calibrations to maximize hot spot detection sensitivity. Thermal-HS is available with a 1024×1024 MWIR sensor for the highest pixel resolution available in an infrared hot spot detection system. QFI has been the world’s leading supplier of infrared hot spot detection systems for many years. The Thermal-HS solution can detect a broader range of defects than liquid crystal, and does so with much greater ease-of-use and sensitivity. QFI offers steady-state hot spot detection, as well as several dynamic techniques for hot spot detection.

Steady-State:

Hot spot detection without power modulation (used by QFI and predecessor since 1960’s) remains the best method for hot spot detection in devices exhibiting high power dissipation and devices, which cannot be modulated and maintain the defect state.

Dynamic Techniques for Hot Spot Detection

In modern IC devices, temperature variations at localized hot spots may only reach µK (microkelvin) levels. Thermal noise and thermal drift complicate the job of detecting these very subtle hot spots. QFI offers several tools to maximize both hot spot sensitivity and the defect capture rate.

Pulse Sampling Thermography (PST):

QFI’s newest quadrature image modulation technique (similar to lock-in amplification) adds bi-level power modulation, bi-mode logic state modulation, and direct extraction of thermal rise time. Thermal rise time extraction is critical for Z-depth capture of hot spot data (important in 3D). PST does not require phase interpretation by the user. Like Modulation Mode below, µK level sensitivity is common.

Modulation Mode

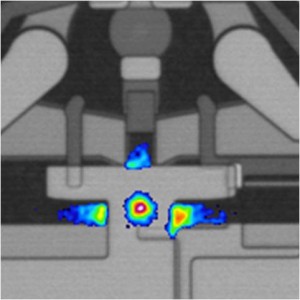

Flexible Design Allows Overlay of Reference Image from Any Sensor Installed on System to MWIR Hot Spot Data Image - (This Example is Overlay of Video Reference Image)

For several years, QFI has offered high sensitivity binary (on/off) power modulation. Modulation Mode couples averaging techniques, and proprietary algorithms to dramatically increase S/N performance and hot spot detection sensitivity. QFI modulation techniques are the most sensitive hot spot detection solutions available (µK level sensitivity is common).

Movie Mode:

Provides dynamic capture of transient events (40 fps to 2000 frames/5 seconds to 10 hours). Allows consecutive playback as movie or step through individual frames. Captures events that no other method will detect like thermal spike at power on.

You are welcome to request additional information via the information request link: